댓글 0

등록된 댓글이 없습니다.

Experiencing vibrations in your vehicle, especially at higher speeds? A common culprit often overlooked is an unbalanced drive shaft. This seemingly simple component plays a crucial role in transferring power from the engine to the wheels. Any imbalance can lead to a cascade of problems, impacting not only your driving comfort but also the longevity of your vehicle.

A drive shaft rotates at high speeds, transferring substantial torque. Even minor imperfections in its weight distribution can generate centrifugal forces. These forces manifest as vibrations that resonate through the vehicle, causing discomfort and potentially damaging other components.

Several factors contribute to drive shaft imbalance. Manufacturing tolerances, wear and tear, and damage from impacts can all disrupt the precise balance required for smooth operation. Over time, even a slight imbalance can worsen, leading to more pronounced vibrations and potential damage to the transmission, differential, and other driveline components.

Ignoring drive shaft imbalance isn't just about enduring a bumpy ride. The persistent vibrations can accelerate wear on bearings, seals, and universal joints. This can lead to premature failure of these components, requiring costly repairs and downtime. Furthermore, the added stress on the drivetrain can negatively impact fuel efficiency.

Beyond the mechanical implications, an unbalanced drive shaft can significantly impact driving comfort. The constant vibrations can be fatiguing, especially on longer journeys. It can also make it difficult to maintain control of the vehicle, especially at higher speeds, compromising safety.

Accurate drive shaft balancing is essential for optimal vehicle performance and longevity. The process involves identifying the points of imbalance and adding or removing weight to achieve uniform weight distribution around the rotational axis. This precision balancing minimizes vibrations, ensures smooth power transfer, and extends the life of driveline components.

Traditional methods often involve static balancing, which addresses imbalance along a single plane. However, for optimal results, dynamic balancing is necessary. Dynamic balancing considers imbalance in multiple planes, providing a more comprehensive solution and eliminating vibrations across the entire operating speed range.

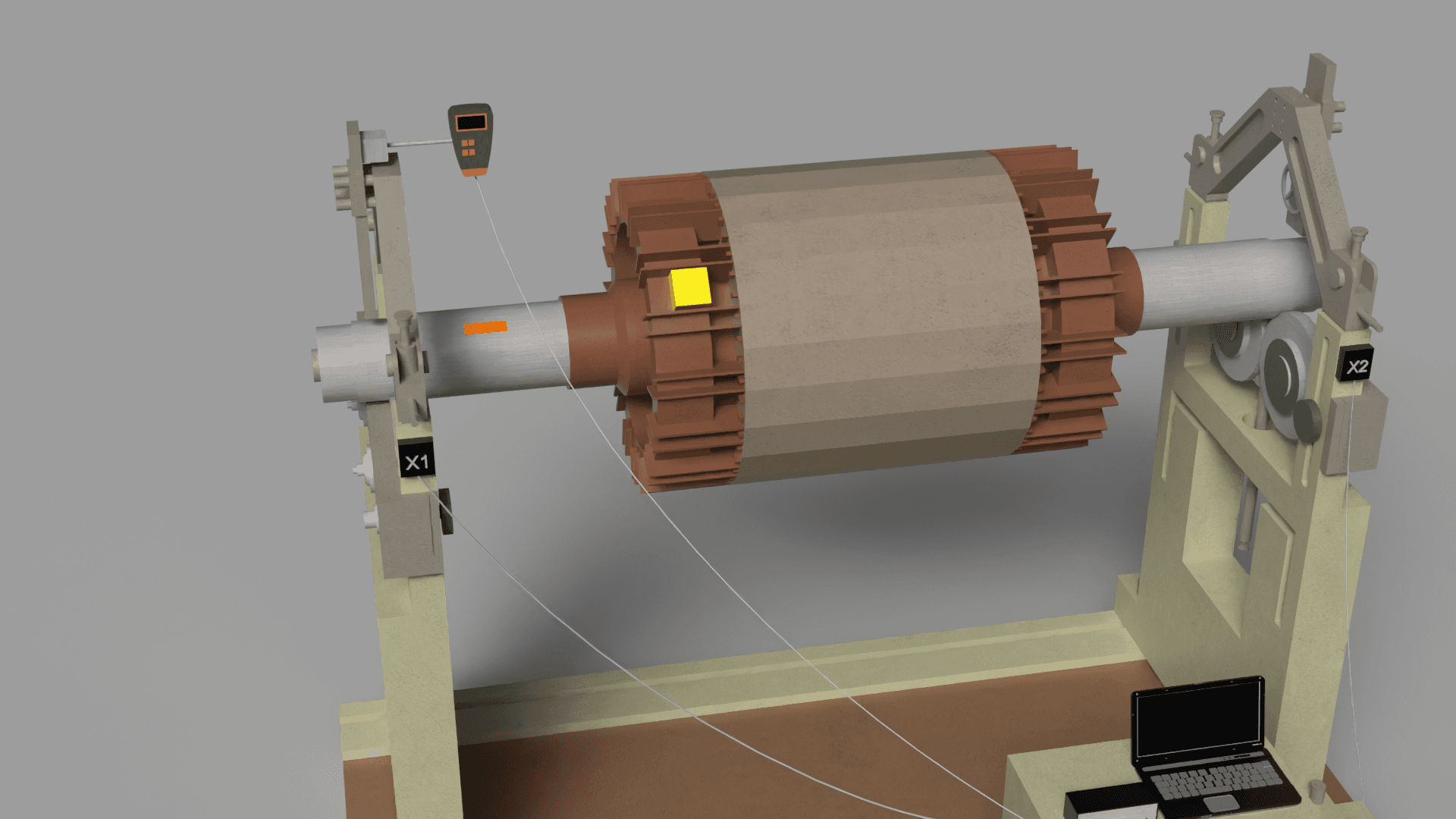

Achieving precise drive shaft balance requires specialized equipment. The Balanset-1A is a state-of-the-art balancing machine designed to provide accurate and efficient dynamic balancing. Its advanced sensors and intuitive software enable technicians to quickly identify and correct even the slightest imbalances.

The Balanset-1A offers a range of features designed to streamline the balancing process. Its user-friendly interface simplifies operation, minimizing training time. The machine's robust construction ensures durability and reliability, making it a valuable investment for any automotive service center.

The Balanset-1A offers numerous advantages over traditional balancing methods. Its precision ensures optimal balancing, eliminating vibrations and extending the life of driveline components. The efficient operation reduces balancing time, increasing productivity and minimizing customer downtime.

Moreover, the Balanset-1A's advanced diagnostics provide detailed reports, enabling technicians to identify potential problems and recommend preventative maintenance. This proactive approach can save significant costs in the long run by preventing major repairs.

A balanced drive shaft is crucial for a smooth, comfortable, and reliable driving experience. The Balanset-1A offers a precise and efficient solution for achieving optimal drive shaft balance. By investing in this advanced balancing technology, you can enhance vehicle performance, extend component life, and ensure customer satisfaction.

Contact us today to learn more about the Balanset-1A and how it can improve your drive shaft balancing operations.

0등록된 댓글이 없습니다.